Cutting and removal

Linjebygg has designed different versions of diamond wire cutting equipment. These saws may be used both topside and in the splash zone, to a depth of 20 m or more, without the support from ROVs. The same diamond wire cutting equipment is suited for cutting at even deeper depths below sea level.

- Low-weight cutting equipment, flexible sizes

- Minimize need for divers or ROV support

- Effective cutting in difficult-to-reach areas

- Turn-key supplier

SUBSEA CUTTING WITH DIAMOND WIRE

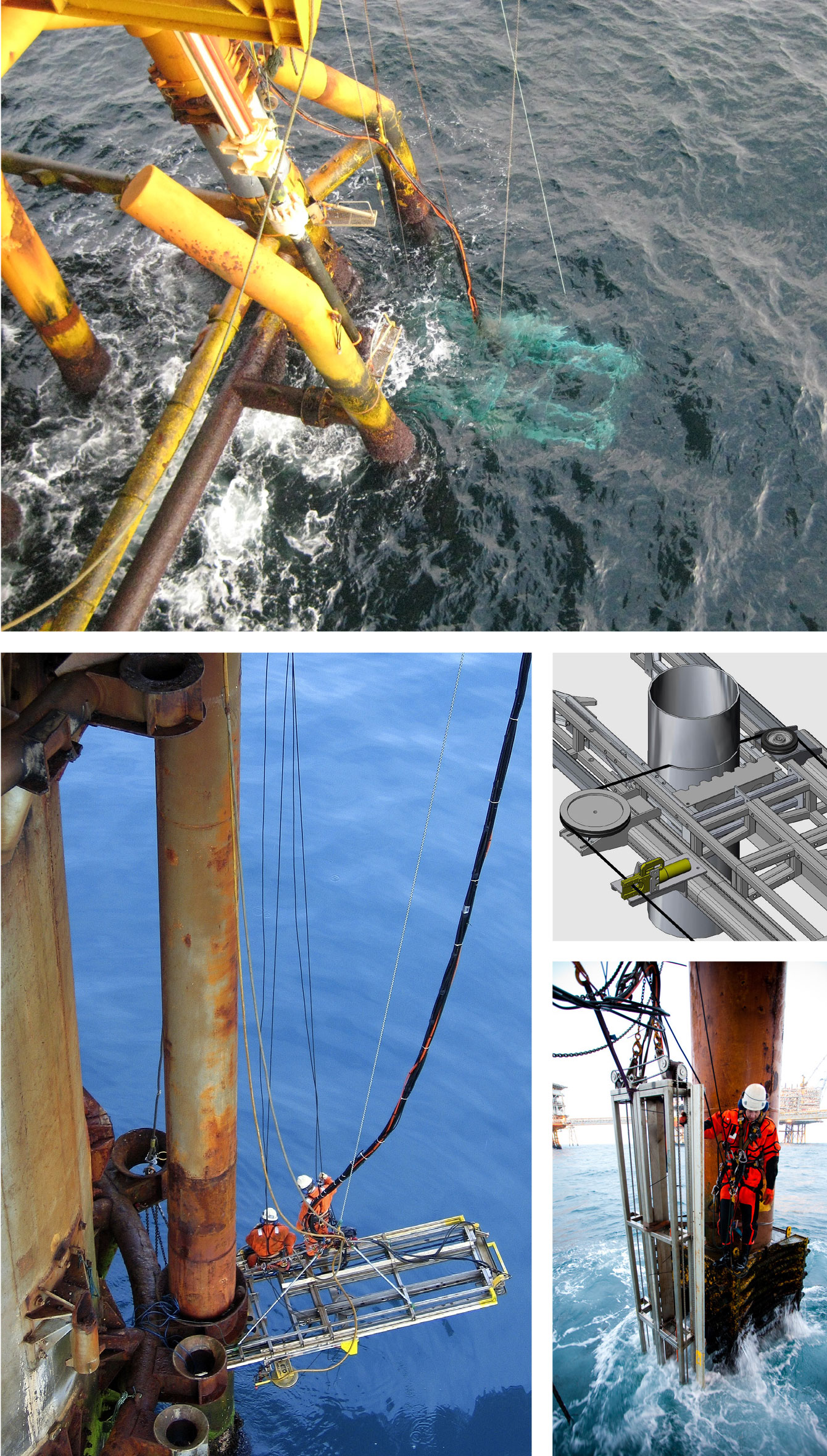

In the nineties Linjebygg was responsible for removing 50 boat bumpers at the Ekofisk field. To work efficiently and safely in the demanding splash zone, a customized diamond wire saw was designed and manufactured.

Since then we have executed a range of cutting projects by using this tool in different configurations and adapted to fit individual project requirements with great success. Its flexibility and mobility, combined with excellent cutting characteristics, makes it a very effective tool for many different cutting operations in the splash zone / subsea such as removal of redundant steel, riser protectors and assistance to heavy lift vessel operations.

EXECUTION

A small, mult-skilled team of rope access technicians and riggers ensures effecient positioning and assembly of the saw. Safe cutting operations are aided by the use of a deck located control cabin, where our operators can remotely monitor and control the cutting process.

Our advanced lifting and rigging methods also reduce or eliminate the need for deck crane or heavy lift vessel assistance for typical “piece-small” cutting operations, and thus contributes to significant cost savings for the customer.

TOPSIDE COLD-CUTTING

Linjebygg has developed a unique ATEX-certified diamond wire cutting kit for cold cutting in explosive areas (*zone 1), to carry out removal and modification work on site without having to shut down the production. The kit is composed of a small but powerful HPU (hydraulic power unit) and a diamond wire saw for easy handling and accessing confined spaces when required.

ATEX-tested

The diamond wire is especially selected for its excellent cutting characteristics. It is ATEX-tested and certified under Linjebygg’s own product code. The HPU has several safety barriers shutting down the system by occurrence of any unexpected failure. The whole cutting kit is tested in an explosive atmosphere by GexCon in Norway according to the ATEX-directive regulations* and certified by DNV.

Cutting of existing equipment and structures are often prime activities related to modification projects on- and offshore in the oil & gas industry. Diamond wire cutting technology has proven its efficiency not only for the traditional rock cutting, but also for cutting black steel, super duplex, S316, titanium, concrete encased steel beams, heavily steel-reinforced concrete, embedded steel structures etc.

ATEX zone 1 (no need for shutdown) and extremely mobile hydraulic power unit.

*Zone 1

HPU specifications

• Weight: 980 kg

• Size: 1535x850x1200mm

• Electricity: 380-690v, 50-60 Hz

• Motor: 40 KW

• Transport: Certified lifting eyes according to DNV 2.7-1, or pallet truck or crane to be applied.

The HPU has a remote control panel with its own frequency, but it can also be connected directly with an internal control cable.