Rigging

Linjebygg provides customized methods and equipment for lifting and rigging operations in difficult to access areas. This type of work requires both the specialist knowledge of the engineering team and the multi discipline skills set out of our workforce executing the complex lifting and rigging operations.

- Minimize use of cranes & support vessels

- Efficient, multi skilled and self-reliant teams

- From planning to offshore execution (EPCI)

- Turn-key supplier

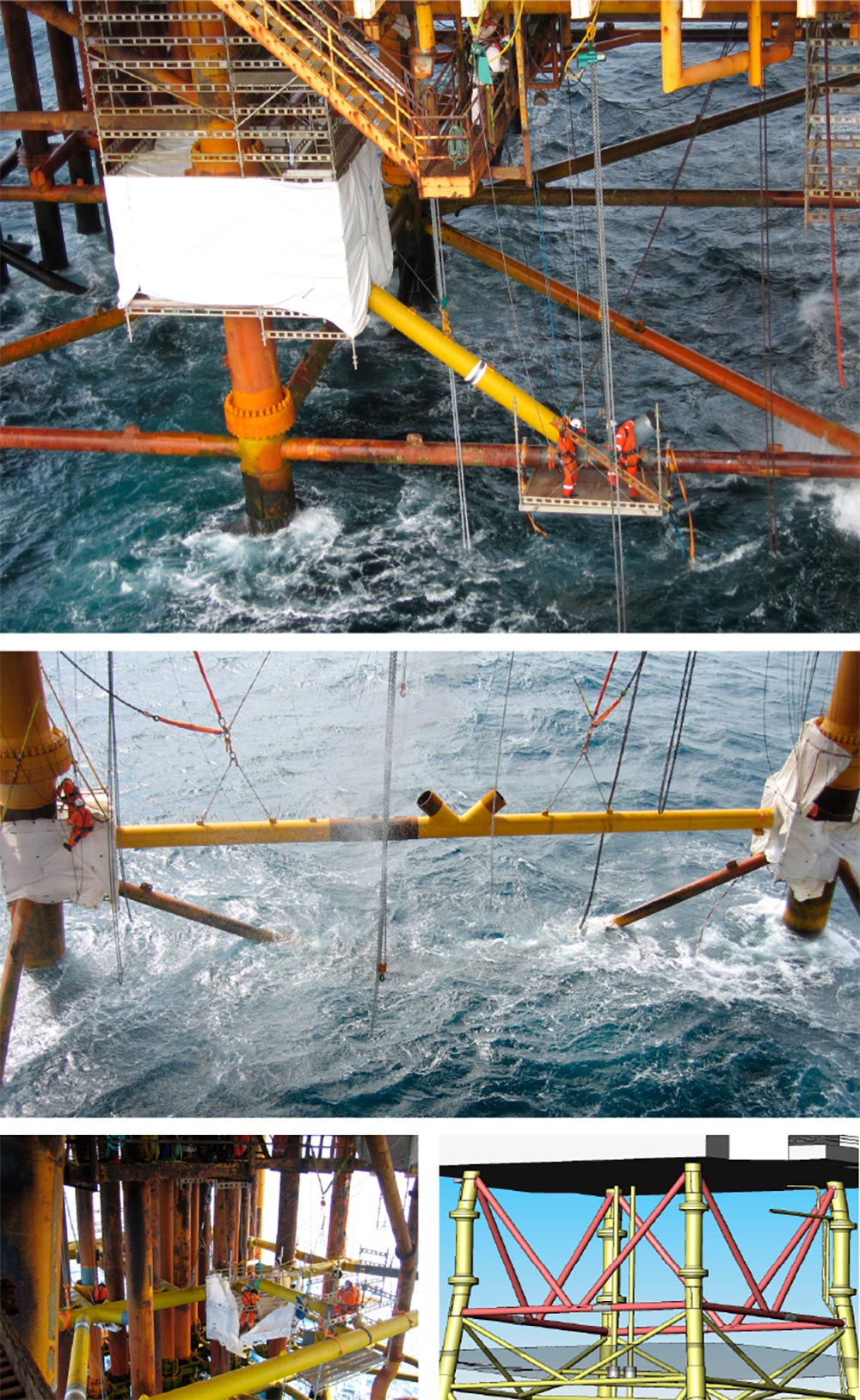

Jacket Reinforcement

Reinforcement of jacket platform structures is challenging due to difficult access and limited or no platform-crane coverage. Weather conditions are another factor affecting such operations, and which must be taken into consideration during the planning to ensure the safety of the workers, equipment and components to be installed.

ENGINEERING AND PROCUREMENT

Experienced Engineers make a site survey to collect comprehensive information. This is followed by detailed design engineering, procurement of materials leading on to manufacture, with full HSE/Q review and documentation at every phase of the project.

Access challenges require specific studies to advise the safest and most suitable installation methods. This is achieved using 3D modeling and CAD techniques.

EXECUTION

Jacket reinforcement challenges both our engineers and the offshore installation staff. However, by careful planning and the use of custom design and built equipment, the execution can be achieved safely and efficiently. The application of suitable lifting systems below deck eliminates the need for deck crane or heavy lift vessel assistance. This in turn helps to reduce the requirement for fair weather dependency.

Close co-operation and pre-planning between our engineers and offshore staff allows for fine tuning of safe and efficient installation operations offshore.

Previous experience and lessons learned are continually fed back by means of a reporting process designed to allow for constant improvement of the engineering, production and installation methodology employed by Linjebygg.

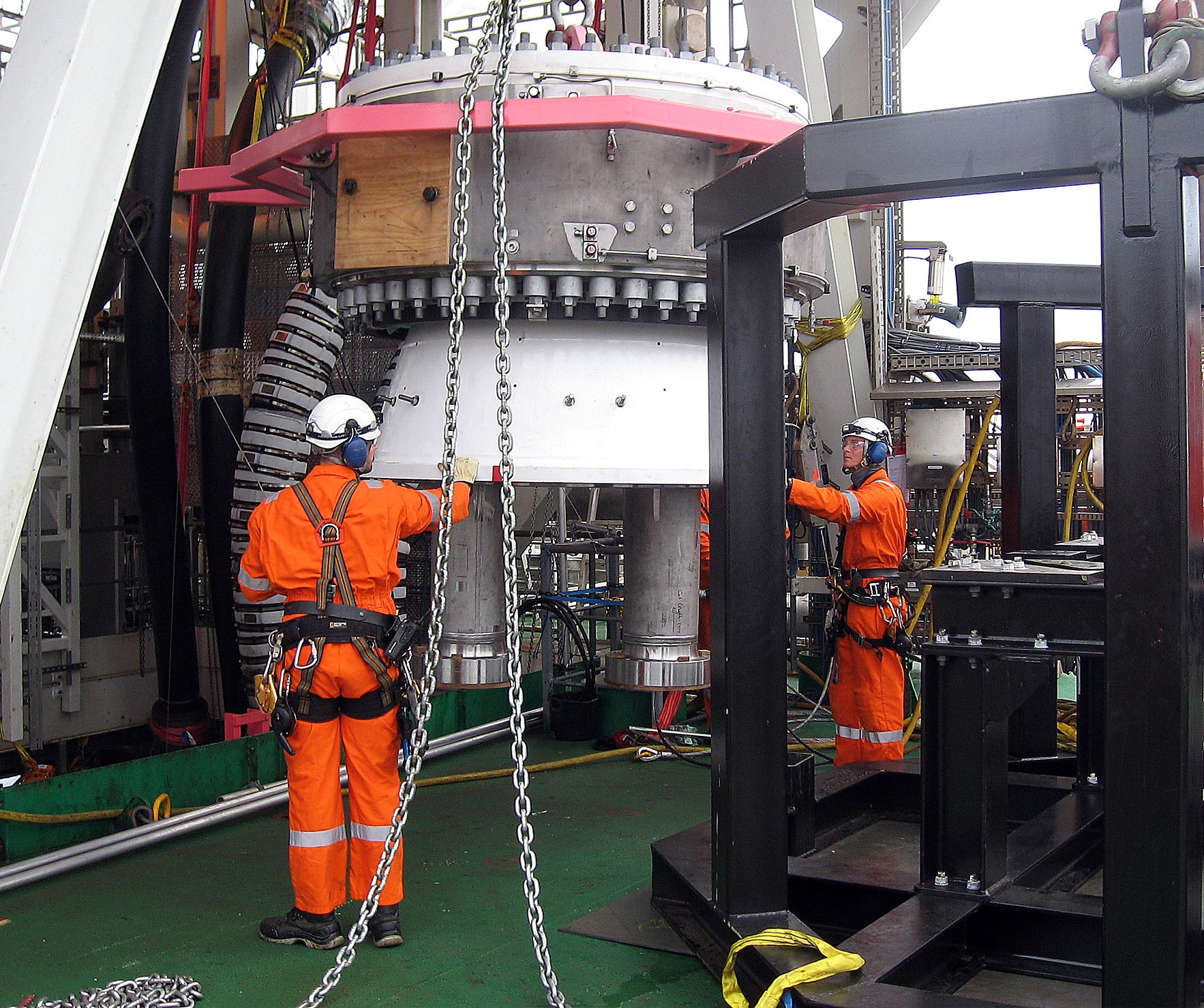

Swivel Replacement & Repair Offshore

Linjebygg’s lifting and rigging competence, together with our engineering expertise, has carried out several swivel replacement projects while the vessel is remained at its offshore location. Our long experience and excellent HSE performance are key elements for such complex rigging operations.

Inspection, maintenance and modification

In 2008, PREZIOSO Linjebygg was responsible

for the lifting and rigging activities on the Norne FPSO Swivel Exchange Project. The great challenge in this project was to remove the old swivel and install the new one while the Norne FPSO remained at its offshore location. Normally similar projects are executed while the FPSO is taken to a suitable dock. Since then we have undertaken several swivel maintenance and modification projects.

ENGINEERING

The lifting and rigging activities in such a challenging task is planned and engineered by PREZIOSO Linjebygg. Studies and preparations of method statements are provided in order to supply the most optimal solution regarding shutdown time and HSE on the FPSO. This includes design and calculation of temporary structure for the lifting and rigging operations.

EXECUTION

Our offshore foremen work closely with the engineering department to provide innovative solutions, and together with a skilled pool of well-trained offshore personnel, they perform the lifting and rigging operations on the FPSO. We have the equipment and tools in our own warehouse, thus we have the possibility to ensure that the operators have the proper training in order to perform safe execution.